Reliable Concrete Scanning Approaches for Construction Tasks

Wiki Article

Introduce the Transformative Power of Concrete Scanning in Making Best Use Of Efficiency and Safety

Concrete scanning has emerged as a critical tool in the building and construction industry, offering unmatched benefits in improving project effectiveness and ensuring safety criteria. By using advanced modern technology, concrete scanning allows experts to see past the surface, revealing hidden complexities that could affect the architectural integrity of a building. The transformative power of concrete scanning exists in its capacity to give real-time information and comprehensive understandings, transforming just how projects are prepared and executed. As we explore the details of this innovative technique, a globe of possibilities opens up, showcasing a new age of building and construction techniques that prioritize accuracy and protection.Significance of Concrete Scanning

Ensuring the structural integrity and safety and security of building and construction projects starts with the vital step of conducting complete concrete scanning. Concrete scanning is a non-destructive technique used to discover and map subsurface elements within concrete structures. This process is essential in determining possible dangers, such as rebar, post-tension cables, and avenues, that may be hidden within the concrete. By utilizing advanced technologies like ground-penetrating radar (GPR) and electromagnetic induction, building groups can accurately find these aspects without triggering any kind of damage to the framework.Additionally, concrete scanning aids in optimizing project timelines and budget by avoiding unanticipated expenses and hold-ups that might arise due to unexpected blockages within the concrete. Ultimately, spending in comprehensive concrete scanning is an aggressive approach that enhances both performance and safety and security in building jobs.

Just How Concrete Scanning Works

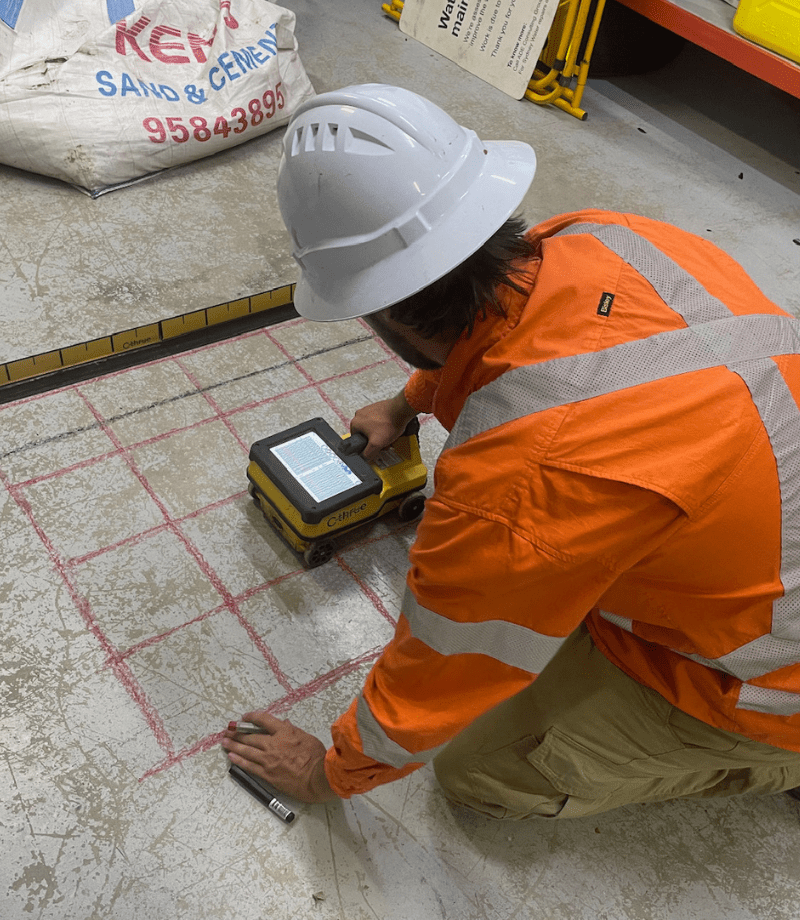

Concrete scanning runs as a vital device in building and construction tasks by employing advanced modern technologies to identify and map subsurface components without creating architectural damage. Ground Passing Through Radar (GPR) and Electromagnetic Induction (EMI) are 2 key methods made use of in concrete scanning. GPR jobs by releasing high-frequency radar pulses right into the surface, which recover when they experience subsurface items or gaps. The time considered the signal to return shows the deepness and area of the objects. EMI, on the other hand, makes use of magnetic fields to recognize differences in product make-ups, such as recognizing rebar or channels within concrete frameworks.Throughout the scanning process, the data accumulated is evaluated in real-time, enabling immediate recognition of prospective dangers or challenges under the surface area. This information help in decision-making, making certain that building and construction tasks proceed safely and effectively. In addition, 3D imaging software program can be made use of to produce thorough maps of the subsurface components, even more improving project preparation and execution. By utilizing these sophisticated innovations, concrete scanning considerably decreases the threat of pricey damages and injuries on building sites.

Advantages of Concrete Scanning

Using innovative scanning innovations in building tasks offers a wide variety of benefits, boosting both efficiency and safety on-site. Among the primary advantages of concrete scanning is the capability to detect and find embedded items such as rebar, post-tension cable televisions, and avenues properly. By identifying these aspects prior to exploration or cutting right into concrete frameworks, the danger of unintended strikes is dramatically minimized, protecting against potential injuries to employees and damage to the structure itself. Furthermore, concrete scanning aids in preparation and designing better, as it gives specific details regarding the area and depth of architectural components.

Study: Concrete Scanning Success

In one more case, a building and construction business made use of 3D concrete scanning to assess the condition old concrete frameworks in a historical structure. The detailed scans supplied beneficial insights right into the extent of deterioration and aided focus on upkeep initiatives successfully. By proactively attending to locations of issue recognized through scanning, the firm had the ability to expand the life-span of the framework and ensure owner security.

These instance studies highlight the transformative power of concrete scanning in boosting efficiency, accuracy, and safety in building projects.

More hints

Applying Concrete Scanning in Projects

Implementing sophisticated scanning technologies during building and construction jobs has become increasingly important for improving precision and security. By integrating concrete scanning into job planning and execution, construction groups can recognize prospective dangers, such as rebar or post-tension cords, concealed within concrete structures. This aggressive method decreases the risk of accidents, hold-ups, and expensive rework, inevitably leading to a lot more reliable job timelines and budgets.To carry out concrete scanning efficiently, job supervisors need to work together very closely with knowledgeable scanning professionals to identify one of the most appropriate scanning techniques for the details project demands. Involving scanning specialists from the beginning of a project enables the group to create detailed scanning plans that attend to crucial areas of problem and ensure comprehensive data collection.

In addition, incorporating concrete scanning right into routine job workflows can enhance decision-making processes, as real-time scan data supplies immediate understandings into the condition of concrete structures - Concrete Scanning. This data-driven technique assists in notified analytical and allows groups to make adjustments without delay, cultivating a society of efficiency and safety and security throughout the task lifecycle

Final Thought

Finally, concrete scanning plays a crucial duty in enhancing performance and security in building projects. By using sophisticated modern technology to map and discover out underlying structures within concrete, this procedure helps to stop expensive errors, make certain structural honesty, and reduce threats on site. With the ability to discover covert components and offer precise information, concrete scanning verifies to be a beneficial device for enhancing project results and making best use of overall success.Concrete scanning is a non-destructive technique used to discover and map subsurface components within concrete frameworks. Furthermore, concrete scanning helps in enhancing Continue task timelines and budget plan by avoiding unexpected expenses and hold-ups that may arise due to unexpected blockages within the concrete. One remarkable instance research study involves a large-scale restoration job where concrete scanning played a critical duty in guaranteeing task success.In another instance, a construction company utilized 3D concrete scanning to assess the condition of maturing concrete frameworks in a historic building. By integrating concrete scanning right into job planning and execution, construction groups can identify potential dangers, such as rebar or post-tension cords, hidden within concrete structures.

Report this wiki page